Predictive Maintenance

(2025-10-02T14:16.339Z)

Perplexity Query

(2025-10-02T14:16

.339Z)

Question:

Write a comprehensive one-page article about "predictive maintenance in advanced manufacturing".

Model: sonar-pro

Predictive Maintenance in Advanced Manufacturing

Introduction

Predictive maintenance is a proactive approach that employs digital technologies—such as IoT sensors, machine learning, and advanced analytics—to predict equipment failures before they happen and optimize maintenance schedules in manufacturing environments.

[8xy6sf]

[u5jsk4]

[s85ak1]

[d5czz7]

Its significance lies in transforming how factories maximize uptime, reliability, and safety by using data-driven foresight rather than reactive, costly repairs. This capability is increasingly important as advanced manufacturing faces rising demand for efficiency, competitiveness, and operational resilience.

Main Content

Predictive maintenance leverages continuous data collection from machinery, paired with real-time monitoring and intelligent analytics, to forecast when maintenance should occur. IoT sensors installed on manufacturing equipment capture data on vibration, temperature, pressure, and operational wear. Machine learning algorithms then process this data, identifying patterns and deviations that signal imminent failure or suboptimal performance.

[8xy6sf]

[s85ak1]

[d5czz7]

Maintenance teams receive alerts when certain thresholds are crossed, enabling timely interventions that prevent breakdowns.

A practical example is in an automotive plant: sensors monitor the health of robotic arms on the assembly line, transmitting their temperature and movement data to a central system. When the analytics platform detects irregular vibrations, a notification is sent to maintenance, allowing replacement of a failing bearing during scheduled downtime rather than risking a line stoppage. Similarly, food processing factories use predictive analytics to anticipate compressor failures, preventing spoilage and maintaining product quality.

[s85ak1]

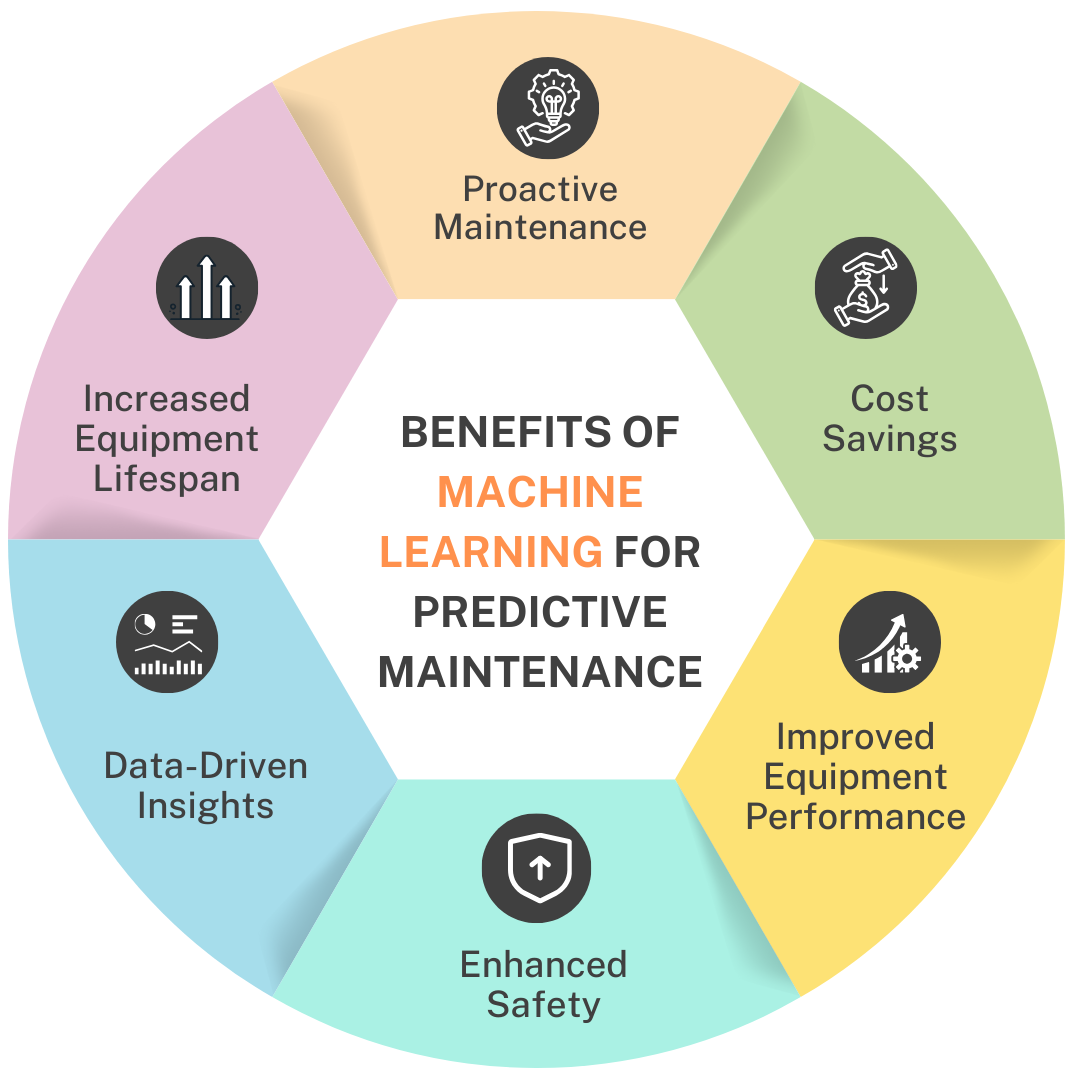

The benefits of predictive maintenance for manufacturers are substantial:

- Smarter inventory management: Predictive models project which components will need attention, decreasing surplus inventory and increasing readiness for critical repairs. [s85ak1]

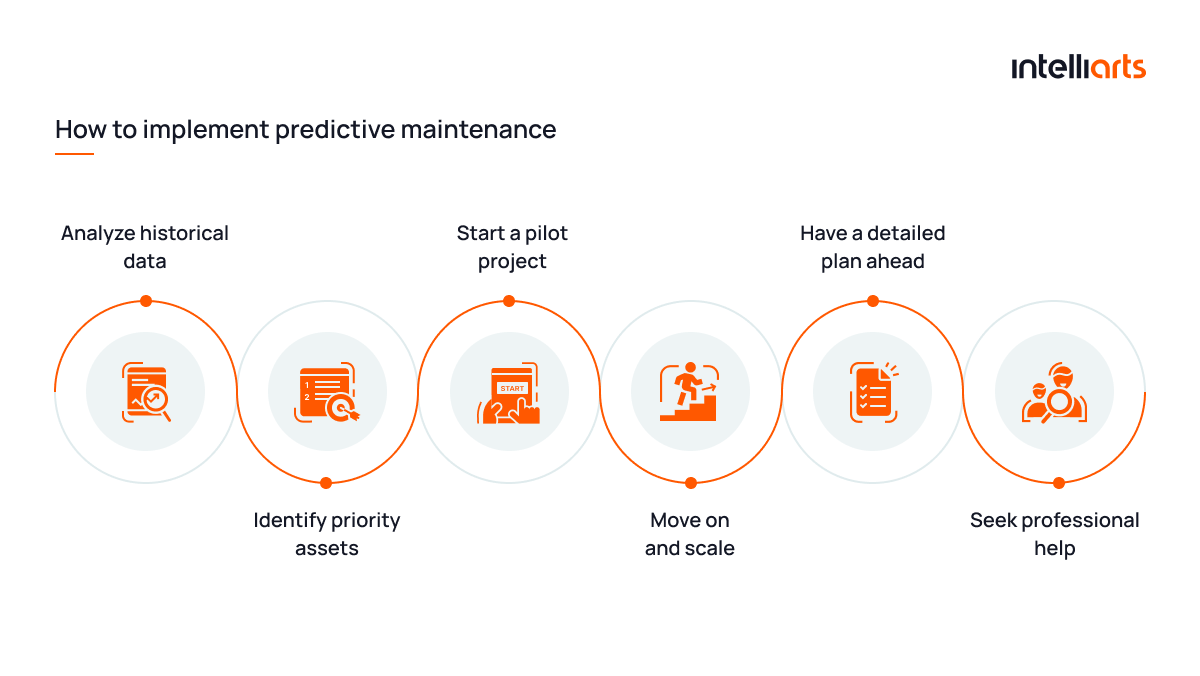

However, implementing predictive maintenance is not without challenges. Manufacturers must address integration of new sensor networks, manage and interpret large volumes of data, and train staff to leverage these systems effectively.

[8xy6sf]

[u5jsk4]

The initial investment can be significant, requiring robust data governance and change management to overcome skill gaps and cultural resistance.

Current State and Trends

Predictive maintenance has seen accelerating adoption in advanced manufacturing, spurred by the falling costs of IoT hardware and the maturation of cloud-based analytics platforms. Leading technology vendors include IBM, Siemens, GE Digital, and SAP, offering integrated solutions that combine sensor networking, data management, and AI-powered analytics.

[d5czz7]

Market analyses indicate strong, sustained growth with predictive maintenance featured as a key component of Industry 4.0 strategies.

Recent developments center on platforms with improved interoperability, cloud-native architectures, and the use of big data to refine predictive algorithms. There is a trend toward integrating predictive maintenance with enterprise resource planning (ERP) and asset management systems, further streamlining workflows and resource allocation. Additionally, manufacturers are leveraging digital twins—virtual replicas of machinery—to simulate wear and predict outcomes more accurately.

Future Outlook

As sensor technology, AI, and cloud systems continue to advance, predictive maintenance will become more autonomous and precise. Future systems will likely feature fully integrated digital twins, prescriptive analytics (not just predicting, but recommending specific actions), and self-adapting algorithms that continuously learn from new data. This evolution promises to further minimize downtime, optimize operational costs, and enable highly flexible, resilient manufacturing networks.

Conclusion

Predictive maintenance is reshaping advanced manufacturing by allowing facilities to optimize productivity, equipment reliability, and safety through data-driven foresight. As adoption rises and technologies mature, it will be a defining enabler for the smart, efficient factories of the future.

Citations

[8xy6sf] 2025, Oct 02. Benefits of Predictive Maintenance in Manufacturing - WorkTrek. Published: 2024-06-24 | Updated: 2025-10-02

[u5jsk4] 2025, Sep 23. Benefits, Challenges & Considerations for Predictive Maintenance. Published: 2025-09-04 | Updated: 2025-09-23

[s85ak1] 2025, Sep 30. The Benefits of Predictive Maintenance in Manufacturing - MaintainX. Published: 2025-08-22 | Updated: 2025-09-30

[d5czz7] 2025, Oct 02. What is Predictive Maintenance? - IBM. Published: 2023-05-09 | Updated: 2025-10-02

[5]: 2025, Jan 23. Definition of Predictive Maintenance: The Key to Industry 4.0 Efficiency. Published: 2025-01-23

[6]: 2025, Sep 30. Benefits of Predictive Maintenance and Preventive ... - TMA Systems. Published: 2000-01-01 | Updated: 2025-09-30

[7]: 2025, Oct 02. Predictive Maintenance Solutions | Deloitte US. Published: 2022-09-26 | Updated: 2025-10-02